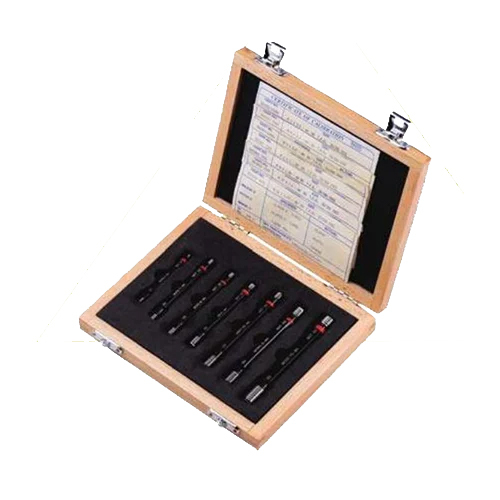

Metric Thread Plug Gauges

Price 1000 INR/ Piece

Metric Thread Plug Gauges Specification

- Measuring Range

- M1 to M100 (Custom sizes available)

- Case

- Plastic or Wooden Protective Case

- Outer Size

- Varies per gauge size (refer to standard)

- Thread

- Metric (ISO) Thread

- Usage

- Industrial

- Size

- M4

- Material

- Steel

- Product Type

- Metric Thread Plug Gauges

- Grade

- ISO Standard / GO & NOGO

- Color

- Black

- Application

- Thread Inspection / Go-No Go Gauging

- Accuracy

- ISO / DIN Standard Tolerance

- Standard Followed

- ISO 1502

- Hardness

- 58-62 HRC

- Calibration

- Traceable to National/International Standards (Calibration Certificate Optional)

- Finish

- Precision Ground, Black Oxide Coated

- Type

- Go/No Go Thread Plug Gauge

- Marking

- Gauges individually marked for size and class

- Interchangeable Handle

- Available on request

- Gauge Length

- As per DIN/ISO specifications

- Packing

- Individual Plastic/wooden box with protective foam

- Class of Fit

- Available in 6g, 6H, or custom classes

Metric Thread Plug Gauges Trade Information

- Minimum Order Quantity

- 1 Piece

- Delivery Time

- 1-7 Days

About Metric Thread Plug Gauges

Exceptional Applications in Industry

Metric Thread Plug Gauges are widely applied in industrial settings for thread inspection and Go/No Go gauging on metal and non-metallic components. These gauges are used to verify ISO metric thread quality, ensuring products meet stringent standards. Their precision-ground finish and black oxide coating suit surfaces requiring eminent accuracy, such as machined parts in automotive, aerospace, engineering, and manufacturing sectors. Benefit from reliable gauge performance on various application surfaces.

Reliable Delivery and Global Export Solutions

FOB Port options are available for international shipments, ensuring seamless goods transport. Upon receipt of a purchase order, delivery times typically range from prompt dispatch to several days depending on gauge size and quantity. List prices are competitive for large orders. Metric Thread Plug Gauges are exported across main markets including Europe, Africa, Asia, and the Middle East. Packaging is tailored to safeguard each product during shipping, whether by sea or air freight.

FAQ's of Metric Thread Plug Gauges:

Q: How does a Metric Thread Plug Gauge ensure accuracy in thread inspection?

A: Metric Thread Plug Gauges are manufactured to ISO/DIN standard tolerance and are precision ground. They are individually marked for size and class, ensuring accurate Go/No Go thread gauging during inspection processes.Q: What application areas benefit the most from these gauges?

A: These gauges are essential in the automotive, aerospace, engineering, and manufacturing sectors-any industry requiring precise thread measurement and quality control on metal and non-metallic components.Q: When should a calibration certificate be requested for a thread plug gauge?

A: A calibration certificate, traceable to national or international standards, is advisable when compliance documentation is required by a quality management system or for critical inspection purposes.Q: Where can you use metric thread plug gauges with black oxide coating?

A: These plug gauges are suitable for application surfaces requiring corrosion resistance and precision finish, making them ideal for factory environments and inspection labs.Q: What is the process for purchasing and receiving these gauges internationally?

A: Simply place a purchase order specifying your requirements; goods are packed individually and shipped from the selected FOB port. Delivery time depends on your location and order volume, with full export documentation provided.Q: How does the interchangeable handle option add value?

A: An interchangeable handle, available upon request, allows for adaptability, easy replacement, and safer handling-ideal for environments requiring multiple gauge inspections.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Thread Gauge Category

Metric Thread Gauge

Price 1000 INR / Piece

Minimum Order Quantity : 1 Piece

Grade : Industrial

Case : Plastic storage case

Outer Size : Standard profile sizes as per DIN/ISO

Thread : Metric

Trapezoidal Thread Gauge

Price 1000 INR / Piece

Minimum Order Quantity : 1 Piece

Grade : Industrial

Case : Hard protective case

Outer Size : As per required gauge size

Thread : Trapezoidal (DIN 103 standard)

Acme And Stub Acme Thread Gauge

Price 1000 INR / Unit

Minimum Order Quantity : 1 Piece

Grade : Industrial

Case : Sturdy Protective Case

Outer Size : Standard as per thread specification

Thread : Acme & Stub Acme

Thread Gauge Set

Price 8530 INR / Piece

Minimum Order Quantity : 1 Piece

Grade : Industrial

Case : Plastic Box

Outer Size : Standard Set Sizes

Thread : Metric & Inch

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry