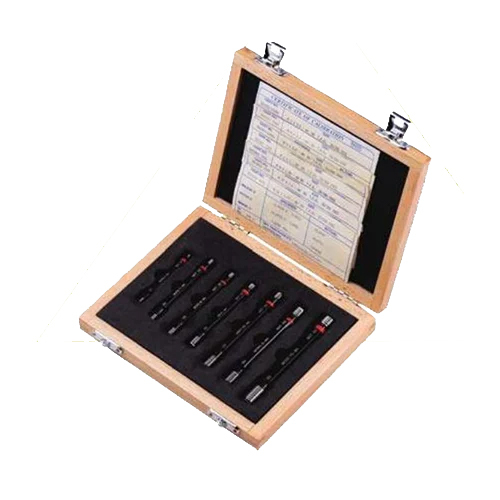

Metric Thread Gauge

Price 1000 INR/ Piece

Metric Thread Gauge Specification

- Display

- Engraved size markings

- Measuring Range

- Metric Threads (various sizes)

- Case

- Plastic storage case

- Thread

- Metric

- Sensor Type

- Thread Gauge

- Outer Size

- Standard profile sizes as per DIN/ISO

- Usage

- Industrial

- Material

- Stainless Steel

- Product Type

- Thread Gauge

- Grade

- Industrial

- Color

- Silver And Black

- Application

- Measuring and checking external and internal metric thread profiles

- Accuracy

- Precision machined to standard tolerances

- Usage

- Manual inspection for machinists and quality control

- Set Contents

- Multiple leaf gauges, each with a different metric thread pitch

- Leaf Thickness

- Standard thickness for easy insertion

- Finishing

- Corrosion-resistant finish

- Marking

- Laser etched or stamped size indicators

Metric Thread Gauge Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 300000 Pieces Per Month

- Delivery Time

- 1-2 Days

- Main Domestic Market

- All India

About Metric Thread Gauge

We are offering Metric Thread Gauge, which is consist of a symmetric V-shaped thread. The flanks of the V are at a 60 angle to one another in the plane of the thread axis. The pitch of the thread is 0.54125. The height H of the V-outside shape and innermost 1/8 and 1/4, respectively, are removed from the profile. Metric Thread Gauge is available in M3 to M12 sizes.

Product details

| Nominal Diameter | M1 to M1.4 |

| Pitch | 0.25 mm |

| Thread Plug | 5 H |

| Thread Ring | 6 H |

| Brand | Baker |

Durable Build, Reliable Performance

Engineered from stainless steel and protected by a corrosion-resistant finish, this metric thread gauge set withstands the demands of industrial use. The standard thickness leaves are precisely machined for seamless insertion, ensuring both longevity and consistent accuracy during repeated applications.

Comprehensive Set for Versatile Application

Each set contains multiple leaf gauges suited for a wide range of metric thread pitches, accommodating various industrial requirements. The engraved size markings, displayed via advanced laser etching or stamping, provide clear, permanent identification, enhancing efficiency in any thread inspection process.

Safe Storage and Easy Transport

The included plastic storage case ensures your thread gauges are easily organized and safely housed when not in use. Its compact, lightweight design makes it simple to transport between job sites or factory floors, minimizing the chance of loss or damage.

FAQ's of Metric Thread Gauge:

Q: How do I use the Metric Thread Gauge to measure thread profiles?

A: To use the Metric Thread Gauge, select a leaf matching the approximate thread pitch of your metric screw, bolt, or nut. Insert the leaf into the threads and ensure the profile aligns perfectly. Repeat with different leaves if necessary until you find an exact match, using the laser-etched or stamped markings to verify the size.Q: What are the benefits of using a corrosion-resistant stainless steel thread gauge?

A: Corrosion resistance extends the lifespan of the thread gauge, ensuring it remains accurate and functional in demanding industrial environments. Stainless steel also resists wear, providing long-term precision when measuring external and internal metric threads.Q: When should I use a metric thread gauge in industrial settings?

A: A metric thread gauge should be used whenever you need to verify or identify the pitch of metric threads during manufacturing, maintenance, or repair tasks. It is invaluable for preventing mismatches, ensuring quality control, and maintaining machinery reliability.Q: Where can I purchase this Metric Thread Gauge set?

A: This gauge set is available through authorized distributors, suppliers, and traders across India. Please consult industrial equipment dealers or reputable online marketplaces specializing in measurement tools for availability.Q: What is the process for checking both external and internal metric threads?

A: For external threads (like bolts), place the correct leaf onto the thread and check for a perfect fit. For internal threads (such as nuts), carefully insert the appropriate leaf and ensure it fills the profile without force or gaps. Always verify the engraved size marking before recording results.Q: What marking methods are used on the leaves, and how does this help usage?

A: Each leaf features laser-etched or stamped size indicators, which provide permanent, highly visible identification. This makes it quick and easy to select the correct size during inspections, even in environments with low lighting or heavy usage.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Thread Gauge Category

Trapezoidal Thread Gauge

Price 1000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Stainless Steel

Application : Other, Measurement and inspection of Trapezoidal threads

Product Type : Trapezoidal Thread Gauge

Outer Size : As per required gauge size

Acme And Stub Acme Thread Gauge

Price 1000 INR / Unit

Minimum Order Quantity : 1 Piece

Material : Stainless Steel

Application : Other, Check Accuracy of Acme & Stub Acme Threads

Product Type : Thread Gauge

Outer Size : Standard as per thread specification

Thread Gauge Set

Price 8530 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Hardened Steel

Application : Other, Internal and External Thread Inspection

Product Type : Thread Gauge Set

Outer Size : Standard Set Sizes

NPTF and ANPT Thread Gauge

Price 1000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Stainless Steel

Application : Other, Thread inspection, Go/NoGo checking for pipes and fittings

Product Type : NPTF and ANPT Thread Gauge

Outer Size : Custom/Standard dependent on thread size

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry