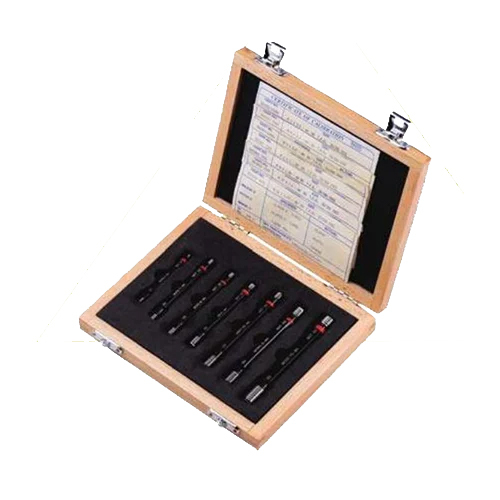

Baker Thread Gauge

Price 1000 INR/ Piece

Baker Thread Gauge Specification

- Thread

- Metric, BSP, BSW, BA, UNC, UNF, and Special threads

- Case

- Protective Case Included

- Measuring Range

- Varies as per Thread Size

- Outer Size

- As per specific gauge

- Usage

- Industrial

- Material

- Stainless Steel

- Seal Material

- Steel / Hardened Steel

- Product Type

- Thread Gauge

- Grade

- Precision / Inspection Grade

- Application

- Thread Inspection, Go/No-Go testing

- Color

- Silver And Black

- Accuracy

- Conforms to relevant standards (ISO, DIN, BS)

- Type

- Go and No-Go Thread Plug and Ring Gauge

- Tolerance Class

- 6H, 6G, or as specified

- Packaging

- Individual protective plastic box

- Standards

- Manufactured as per ISO, DIN, BS, or customer specification

- Hardness

- Hardened to 58-62 HRC

- Marking

- Laser Engraved Size and Type on Gauge Body

- Finish

- Chrome or Black Oxide finish

Baker Thread Gauge Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 300000 Pieces Per Month

- Delivery Time

- 1-2 Days

- Main Domestic Market

- All India

About Baker Thread Gauge

We are supplying Baker Thread Gauge, which is intended to establish both the exterior and internal threads gradient. The pitch or lead of a screw head can be measured with a thread gauge. In metal turning lathes, thread gauges are useful for gauging tool angle as threads are being cut. Baker Thread Gauge does the precise measurement is just a little smaller than the named or nominal size.

Product details

|

Accuracy |

6H |

|

Application |

Working Gauges |

|

Tolerance |

6H , 6g |

|

Measuring Range |

M1 to M30 |

|

Brand |

Baker |

Unmatched Precision and Durability

Baker Thread Gauges offer exceptional durability and accuracy, crafted from stainless and hardened steel with a corrosion-resistant chrome or black oxide finish. Their robust construction ensures consistent performance under rigorous industrial usage while the 58-62 HRC hardness provides excellent wear resistance.

Versatile Thread Compatibility

These gauges accommodate a wide variety of thread types, such as Metric, BSP, BSW, BA, UNC, UNF, and custom specifications. This versatility allows them to be employed across different industries and applications, facilitating comprehensive thread inspection and quality assurance for manufacturing and engineering processes.

Comprehensive Packaging and Marking

Each gauge is securely packaged in an individual protective plastic box, with clear laser-engraved size and type marking on the body for effortless identification. The inclusion of a robust case further protects the instrument, ensuring longevity and easy handling during storage and transport.

FAQ's of Baker Thread Gauge:

Q: How are Baker Thread Gauges used for Go/No-Go testing?

A: Baker Thread Gauges are specifically designed for Go/No-Go testing, which determines whether a threaded part meets the required dimensional tolerances. The 'Go' gauge should fit the thread correctly, while the 'No-Go' gauge must not; this ensures that threads are within acceptable limits for industrial use.Q: What thread types and tolerance classes do these gauges support?

A: These gauges are compatible with Metric, BSP, BSW, BA, UNC, UNF, and special threads. They can be manufactured with tolerance classes such as 6H, 6G, or as specified by the customer, conforming to international standards or unique requirements.Q: When should I use a Gauge with a chrome finish versus a black oxide finish?

A: A chrome finish is recommended for environments where corrosion resistance and high visibility are important, while a black oxide finish is preferred for reducing glare and offering a more cost-effective corrosion protection in milder settings. The choice largely depends on your application's requirements and exposure conditions.Q: Where are Baker Thread Gauges manufactured and distributed?

A: Baker Thread Gauges are manufactured in India, adhering to ISO, DIN, or BS standards. They are distributed and supplied by authorized distributors, suppliers, and traders across various industrial sectors within India and internationally.Q: What is the process for marking and packaging the gauges?

A: Each gauge is laser engraved with size and type information directly onto its body to ensure permanent identification. For protection, every gauge is placed inside an individual plastic box and comes with a sturdy case, safeguarding it during storage and transportation.Q: What benefits do precision/inspection grade gauges provide?

A: Precision or inspection grade gauges ensure high measurement reliability and repeatability, which are critical for quality assurance in manufacturing. Their conformity to strict international standards guarantees dimensional accuracy and consistent thread testing results, reducing the risk of defective components entering production.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Thread Gauge Category

Trapezoidal Thread Gauge

Price 1000 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Trapezoidal Thread Gauge

Material : Stainless Steel

Usage : Industrial

Measuring Range : Varies by thread size

Hole Location Thread Gauge

Price 2500 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Hole Location Thread Gauge

Material : Stainless Steel

Usage : Industrial

Measuring Range : As per thread size

Thread Gauge Set

Price 8530 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Thread Gauge Set

Material : Hardened Steel

Usage : Industrial

Measuring Range : Various (as per set)

Metric Thread Plug Gauges

Price 1000 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Metric Thread Plug Gauges

Material : Steel

Usage : Industrial

Measuring Range : M1 to M100 (Custom sizes available)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry