Baker G Pipe Thread Gauge

Price 1000 INR/ Piece

Baker G Pipe Thread Gauge Specification

- Outer Size

- Varies with gauge size (Refer to specific gauge size chart)

- Measuring Range

- G 1/16 to G 6 inch (Various sizes available)

- Thread

- ISO 228 (BSPP - British Standard Pipe Parallel)

- Case

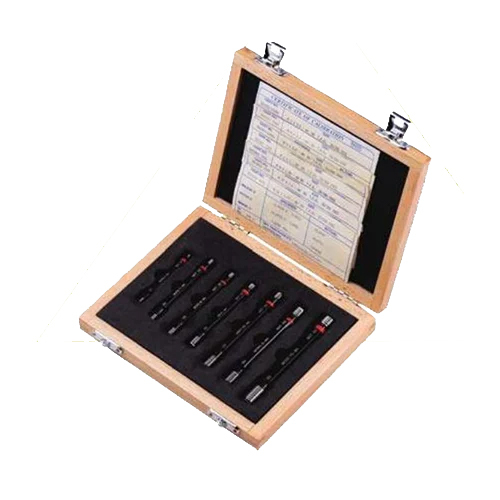

- Protective Case Included

- Usage

- Industrial

- Material

- Stainless Steel

- Product Type

- G Pipe Thread Gauge

- Grade

- Industrial Grade

- Color

- Silver And Black

- Application

- Inspection and checking of G series pipe thread (BSPP) for accuracy

- Accuracy

- As per ISO 228 Standard

- Gauge Class

- Class A / Class B available

- Rust Protection

- Anti-corrosive coating for extended tool life

- Packing Type

- Individual hard case or protective box

- Type

- Go and No-Go Plug / Ring Gauge

- Identification Marking

- Clearly engraved size and identification markings

- Manufacturing Standard

- Certified to ISO 228, IS : 2643, DIN 259 specifications

- Thread Direction

- Right Hand

- Finish Type

- Precision Ground Finish with Hard Chrome Plating (optional)

Baker G Pipe Thread Gauge Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 300000 Pieces Per Month

- Delivery Time

- 1-2 Days

- Main Domestic Market

- All India

About Baker G Pipe Thread Gauge

Product details

| Precision | 6H, 7H |

| Material | Stainless Steel |

| Size | M1-M56 |

| Brand | Baker |

Certified for Accuracy and Reliability

Baker G Pipe Thread Gauges are certified to international standards including ISO 228, IS:2643, and DIN 259, ensuring consistent and dependable performance. Engineered for industrial environments, each gauge undergoes strict quality checks, guaranteeing the highest precision and reliability during BSPP thread inspection tasks.

Versatile and Durable Build

Constructed with premium stainless steel and finished to a precision ground surface, these gauges provide robustness and resistance to industrial wear. Optional hard chrome plating and an anti-corrosive coating ensure durability, making these gauges suitable for demanding inspection procedures in any industrial workspace.

Effortless Identification and Extended Tool Life

The gauges feature clear, permanent size and identification markings, simplifying usage and traceability. Packaged individually in a durable hard case, each gauge is protected from damage and corrosion, offering extended usability and consistent measuring performance for professionals across industries.

FAQ's of Baker G Pipe Thread Gauge:

Q: How do you use the Baker G Pipe Thread Gauge for BSPP thread inspection?

A: To use the Baker G Pipe Thread Gauge, select the correct Go and No-Go gauge for your BSPP thread size. Insert the Go end to check for correct thread dimensions; it should fit easily. Use the No-Go end to ensure threads are not too loose, as it should not fit. This process helps verify thread compliance with ISO 228 standards.Q: What are the benefits of the precision ground finish with optional hard chrome plating?

A: The precision ground finish ensures accurate and smooth gauge surfaces, which enhances measurement precision. Optional hard chrome plating provides extra hardness, improved wear resistance, and protection against corrosion, leading to a longer service life for the gauge in industrial settings.Q: When should you choose Class A versus Class B gauge?

A: Class A gauges are ideal for high-precision, quality control environments where the tightest tolerances are required. Class B gauges offer suitable accuracy for general inspection and maintenance tasks. Your selection depends on the criticality of the inspection process and specific industry requirements.Q: Where are these pipe thread gauges commonly used?

A: Baker G Pipe Thread Gauges are widely used across industries, including manufacturing, plumbing, oil and gas, and engineering workshops. They are ideal for any industrial setting that requires reliable inspection and checking of British Standard Pipe Parallel (BSPP) threads.Q: What is included with each purchase of a Baker G Pipe Thread Gauge?

A: Each gauge comes in an individual hard case or protective box, providing secure storage and protection against environmental factors. The case helps prevent damage and extends the life of the gauge, making it easy to store and transport.Q: Why is anti-corrosive coating important for these gauges?

A: The anti-corrosive coating protects the gauge from rust and environmental degradation, especially in humid or challenging industrial environments. This feature ensures consistent accuracy and extends the usable life of the gauge, providing better value and reliability.Q: How can you identify the correct gauge size and type quickly?

A: Each Baker G Pipe Thread Gauge has clearly engraved size and identification markings on its surface. This clear labeling allows users to quickly select the correct gauge for any inspection process, reducing the risk of selecting the wrong tool during critical operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Thread Gauge Category

Metric Thread Gauge

Price 1000 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Thread Gauge

Usage : Industrial

Measuring Range : Metric Threads (various sizes)

Outer Size : Standard profile sizes as per DIN/ISO

Baker Thread Gauge

Price 1000 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Thread Gauge

Usage : Industrial

Measuring Range : Varies as per Thread Size

Outer Size : As per specific gauge

Thread Gauge Set

Price 8530 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Thread Gauge Set

Usage : Industrial

Measuring Range : Various (as per set)

Outer Size : Standard Set Sizes

G Pipe Thread Gauge

Price 1000 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : G Pipe Thread Gauge

Usage : Industrial

Measuring Range : Size Range G1/16 to G6

Outer Size : Depends on Gauge Size Standard as per BS 2779/ISO 2281

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry