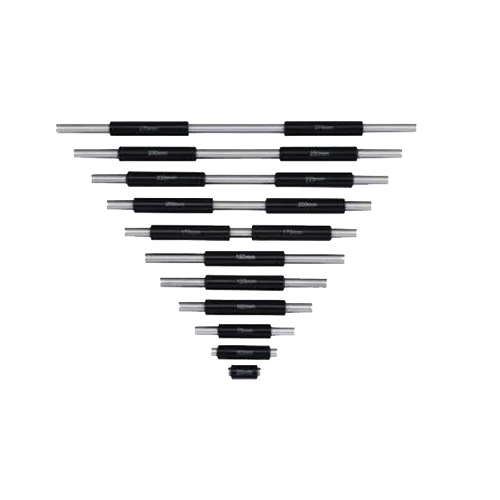

Setting Gauge Micrometer

Price 1000 INR/ Piece

Setting Gauge Micrometer Specification

- Display Type

- Analog (Thimble Scale) or Digital

- Resolution

- 0.001 mm

- Interface Type

- Manual

- Response Time

- Instantaneous

- Equipment Type

- Setting Gauge Micrometer

- Color

- Silver

- Features

- Locking Clamp, Carbide Measuring Faces, Ratchet Stop, Satin Chrome Finish

- Mounting Type

- Handheld / Bench Mounted

- Measuring Range

- 0-25 mm (typical), other ranges available

- Automation Grade

- Manual

- Accuracy

- 0.001 mm

- Usage

- Industrial

- Application

- Precision Measurement, Calibration, Setting Reference for Other Instruments

- Product Type

- Setting Gauge Micrometer

- Operating Environment

- Laboratory, Workshop

- Finish Type

- Satin Chrome

- Contact Faces

- Hardened and Lapped

- Material

- Stainless Steel / Alloy Steel

- Frame Shape

- C-Frame

- Scale Graduation

- 0.01 mm

Setting Gauge Micrometer Trade Information

- Minimum Order Quantity

- 1 Piece

- Delivery Time

- 1-7 Days

- Main Domestic Market

- All India

About Setting Gauge Micrometer

Noteworthy Features and Versatile Applications

The Setting Gauge Micrometer offers unmatched precision, making it suitable for both industrial and laboratory use. Its sublime accuracy and top-tier build ensure it serves as a reliable calibration instrument or a setting reference for other measuring tools. The elite hardened, lapped carbide measuring faces and satin chrome finish enhance durability, while features like a locking clamp and ratchet stop provide secure and consistent measurements. Reserve it for noteworthy tasks where precision and reliability are paramount.

Quick Dispatch and Reliable Logistics for Elite Tools

Our Setting Gauge Micrometers are available for prompt delivery through trusted FOB ports across India. With streamlined logistics and consistent supply ability, we guarantee quick dispatch and timely delivery regardless of order size. Traders, distributors, and suppliers benefit from our transparent list price structure and efficient service. Reserve your top-tier precision solution and experience best-in-class support for all your industrial and laboratory measuring requirements.

FAQ's of Setting Gauge Micrometer:

Q: How is the Setting Gauge Micrometer used in precision measurement?

A: The Setting Gauge Micrometer is used to perform highly precise measurements, calibration, and serve as a setting reference for other instruments in both laboratory and industrial environments, thanks to its high accuracy and resolution.Q: What advantages do the hardened and lapped contact faces offer?

A: The hardened and lapped contact faces provide exceptional wear resistance, ensure longevity, and maintain measurement accuracy, making the micrometer highly suitable for rigorous applications.Q: When should I choose a Setting Gauge Micrometer with a digital versus analog display?

A: Digital displays offer easy readability and reduce reading errors, while analog thimble scales are preferred for traditional users or settings where visual confirmation is crucial. Your choice depends on workflow preferences and application needs.Q: Where can this micrometer be mounted for effective use?

A: The Setting Gauge Micrometer can be used as a handheld device or bench-mounted, providing flexibility for both laboratory and workshop setups, enhancing convenience and precision during measurement tasks.Q: What is the process for calibrating the Setting Gauge Micrometer?

A: Calibration involves comparing the device against a standard of known accuracy, adjusting as needed to align with precision criteria. Routine calibration ensures the instrument remains a reliable reference for other measuring tools.Q: What benefits does the satin chrome finish provide?

A: The satin chrome finish prevents glare, resists surface wear, and ensures longevity, allowing easy reading of the scale markings in various lighting conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in External Micrometer Category

MM25-HT Micrometer Head

Price 1420 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Industrial

Product Type : Micrometer Head

Test Range : 025 mm / 01"

Color : Silver

MMC 25-ND External Disk Micrometer

Price 7650 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Industrial

Product Type : External Disk Micrometer

Test Range : 025 mm / 01"

Color : Silver

INC 25-ND External Disk Micrometer

Price 7650 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Industrial

Product Type : External Disk Micrometer

Test Range : 025 mm / 01"

Color : Silver

Micrometer Heads With Non-Rotating Spindle

Price 1300 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Industrial

Product Type : Micrometer Heads With NonRotating Spindle

Test Range : 025mm

Color : Silver

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry